Developing an Open-Source, Miniature Manipulation Device

Micro-Manipulator with Sub-Micron Precision Developed by Diffraction Limited

Diffraction Limited, a leading company in the field of photonics and micro-manipulation, has unveiled a new micro-manipulator capable of sub-micron precision. This innovative device, developed by Prof. Dr. Oliver G. Schmidt and his team at the TU Chemnitz research center, is set to revolutionise various small-scale manufacturing methods.

The micro-manipulator, unlike many of its counterparts, does not rely on internal charge pumps or clocked logic units in its motor drivers. This design choice minimises timing errors and motion jitter, ensuring smooth and accurate movements. The motor drivers are controlled by a Raspberry Pi Pico 2, with three motor drivers powering the micro-manipulator's system.

The micro-manipulator's stage can move 23 mm in each direction due to the wide range of allowed angles. This mobility, combined with its high precision, makes it an ideal tool for a variety of applications. Diffraction Limited plans to utilise the micro-manipulator for maskless lithography, electrochemical 3D printing, focus stacking, and micromachining. The company is even considering using it in a "wafer stepper" for maskless lithography.

The stepper motors in the micro-manipulator are controlled using closed-loop control provided by a magnetic rotary encoder. This encoder can divide a single rotation of a magnet into 100,000 steps, offering exceptional accuracy and repeatability. To further enhance the resolution of the magnetic rotary encoder, Diffraction Limited added an array of alternating-polarity magnets to the rotor and positioned the magnetic encoder near these.

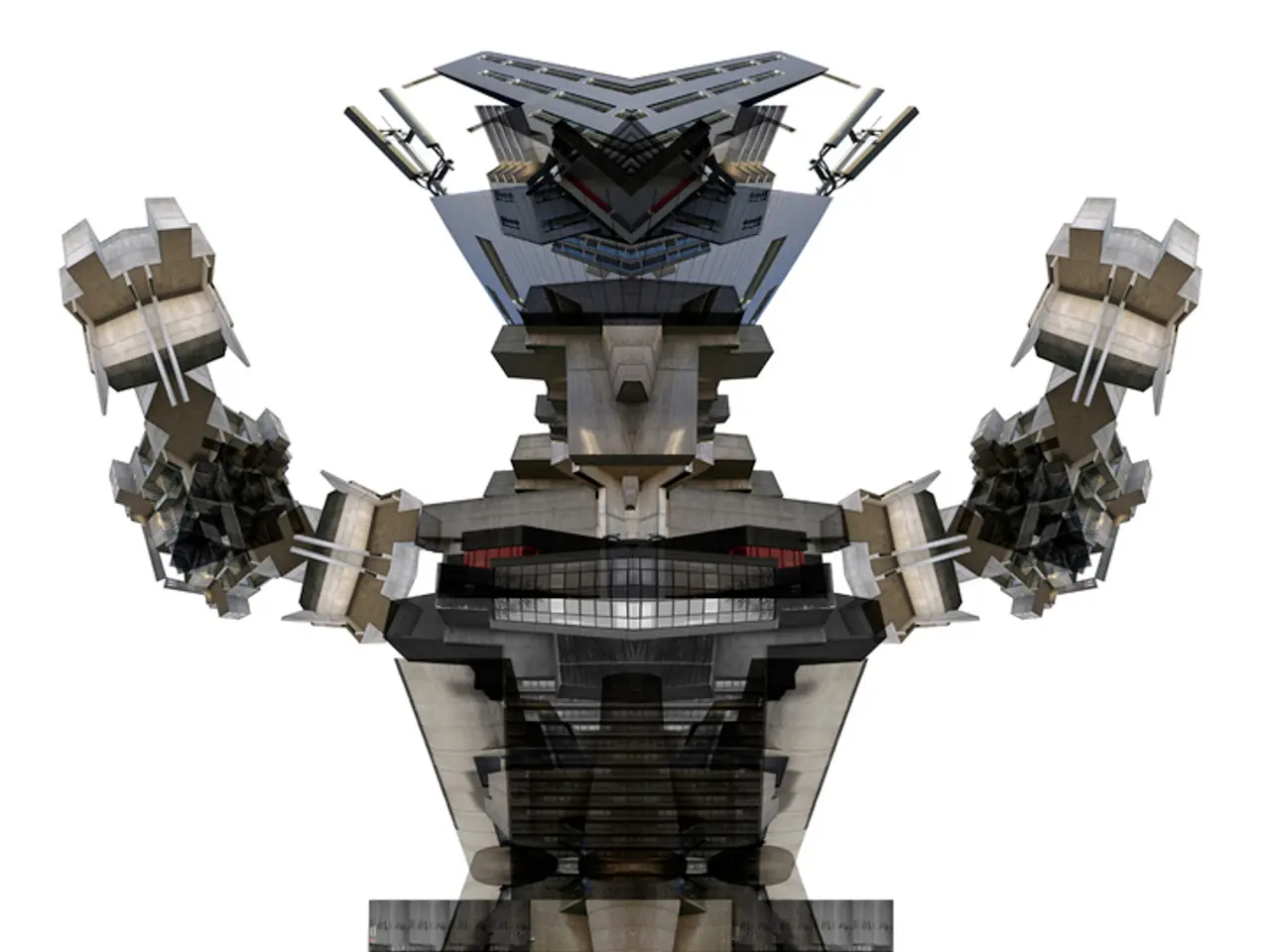

The micro-manipulator's design is both innovative and practical. It consists of a mobile platform supported by three pairs of parallel linkages, each actuated by a stepper motor. Instead of using flexures, the linkages swivel on ball joints, providing flexibility and durability.

The carrier circuit board of the micro-manipulator is double-sided and uses through-hole components for ease of replication. The lower silkscreen displays pin numbers, making assembly and maintenance straightforward.

Diffraction Limited has already demonstrated the micro-manipulator's capabilities by using it to position a chip die under a microscope. It was also tested for accuracy and repeatability by tracing a path generated for the first layer of a Benchy, a popular 3D print model. The micro-manipulator was able to trace a Benchy within a 20-micrometer square when run slowly, showcasing its impressive precision.

Another promising small-scale manufacturing method is the RepRapMicron. While the micro-manipulator and the RepRapMicron serve similar purposes, they each have their unique strengths. The micro-manipulator's precision and versatility make it a valuable tool for a wide range of applications, while the RepRapMicron focuses on low-cost, easy-to-replicate manufacturing.

As the world of small-scale manufacturing continues to evolve, the micro-manipulator developed by Diffraction Limited is set to play a significant role. Its precision, versatility, and practical design make it a powerful tool for researchers, engineers, and manufacturers alike.