Importance of Pneumatic Cylinders in Accurate Automation Systems

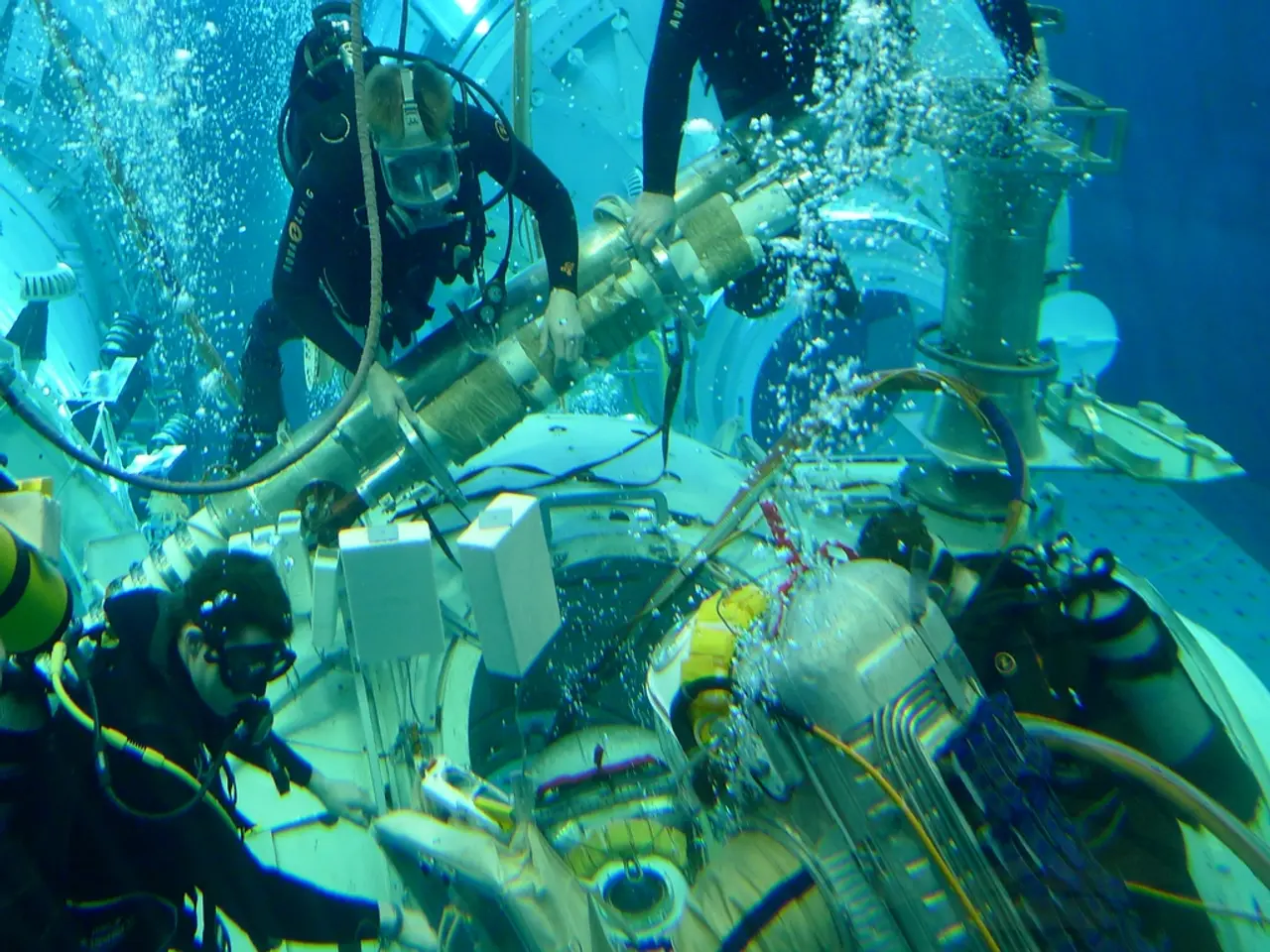

In the realm of industrial automation, pneumatic cylinders often go unnoticed yet play a crucial role in powering various machines. These components serve as linear actuators, enabling moving, stopping, and controlling robotic arms, among other functions.

Several companies in Germany offer specialized pneumatic cylinders suitable for precision automation. SMC Deutschland, a leading expert in pneumatic and electric automation, has recently strengthened its offerings through a new distribution partnership with LOTZ Hydraulik + Pneumatik. Enerpac, while primarily focused on hydraulic solutions, also provides high-precision hydraulic solutions relevant to industrial automation. For pneumatic tubing, PAPUREX offers high-quality polyurethane hoses made in Germany, essential components of precision automation systems.

When selecting a pneumatic cylinder, matching the bore and stroke is necessary but not sufficient. Engineers must also consider stroke and load, speeds and acceleration rates, environmental conditions, mounting configuration, feedback and sensor integration, and more. Guided cylinders are useful for side loads or critical alignments, ensuring optimal motion control, while rodless cylinders are beneficial for applications with long strokes and space limitations.

Proper mounting ensures the unit functions optimally and prolongs service life by improving alignment and reducing vibration. Real-time feedback is often provided by pneumatic cylinders through integrated magnetic sensors, monitoring stroke position.

Working with a reliable platform like Omchele offers numerous advantages. Product transparency, customization support, logistics and scalability, verified quality, and integrated services are just a few benefits. A reliable platform ensures punctual delivery, effective bulk order processing, and rapid reorder steps for maintenance and scaling.

Omchele is a B2B marketplace that offers full consideration of requirements from the start, preventing expensive rework or downtime. Platforms like Omchele provide direct B2B needs pertaining to specifications, support, customizations, and tailored solutions for businesses.

Ignoring load dynamics, such as weight changes or sudden shifts in direction, can risk a system's reliability and durability. Incorrect selection of pneumatic cylinders can impact the effectiveness and reliability of an entire system for a long time. Vendors can become advanced automation partners by offering additional services such as pneumatic circuit design assistance, replacement parts, and installation help.

Maintenance procedures can become challenging when components are stored in inaccessible locations. Environmental conditions, such as excessive dust, heat, moisture, or exposure to chemicals, require materials like stainless steel or coated aluminum to prevent corrosion and degradation.

Data and QA standards validate the product's value and enhance trust in its durability. Double-acting cylinders apply air pressure on each side of the piston alternately, providing two directional movement. Single-acting cylinders require air pressure to move in one direction and are suitable for small-scale tasks with no sophisticated requirements.

Issues that can arise from poor pneumatic cylinder selection include motion precision setbacks, unnecessary damage, vibration and imbalance within the system, consumed electrical power, risks of injuries and accidents. Pneumatic cylinders are essential components in industrial automation, often overlooked.

Feedback and sensor integration are vital for monitoring and controlling the piston's movement dynamics in automated systems. Speeds and acceleration rates are important for dynamic and fast-paced automation. Neglecting these factors can lead to inefficiencies and potential system failures.

In conclusion, the selection of pneumatic cylinders is a critical decision in the realm of precision automation. By considering factors such as stroke and load, environmental conditions, mounting configuration, feedback and sensor integration, and working with reliable partners like Omchele, businesses can ensure the efficiency, reliability, and safety of their industrial automation systems.

Read also:

- Asthma Diagnosis: Exploring FeNO Tests and Related Treatments

- Potential Dangers of Bed Rails: Protecting Your Family Members from Entrapment Hazards

- Expanding Representation in Rural Noir Narratives: A Call for More Queer Female Characters

- Intensive firefighting assistance through Airbus technological solutions