Nuclear reactor corrosion and cracking can now be tracked using a novel approach

In a groundbreaking development, researchers from MIT and Rensselaer Polytechnic Institute have developed a technique for real-time, 3D monitoring of corrosion, cracking, and other material failure processes inside a nuclear reactor environment. This breakthrough could lead to the design of safer and higher-performing nuclear reactors for applications like electricity generation and naval vessel propulsion.

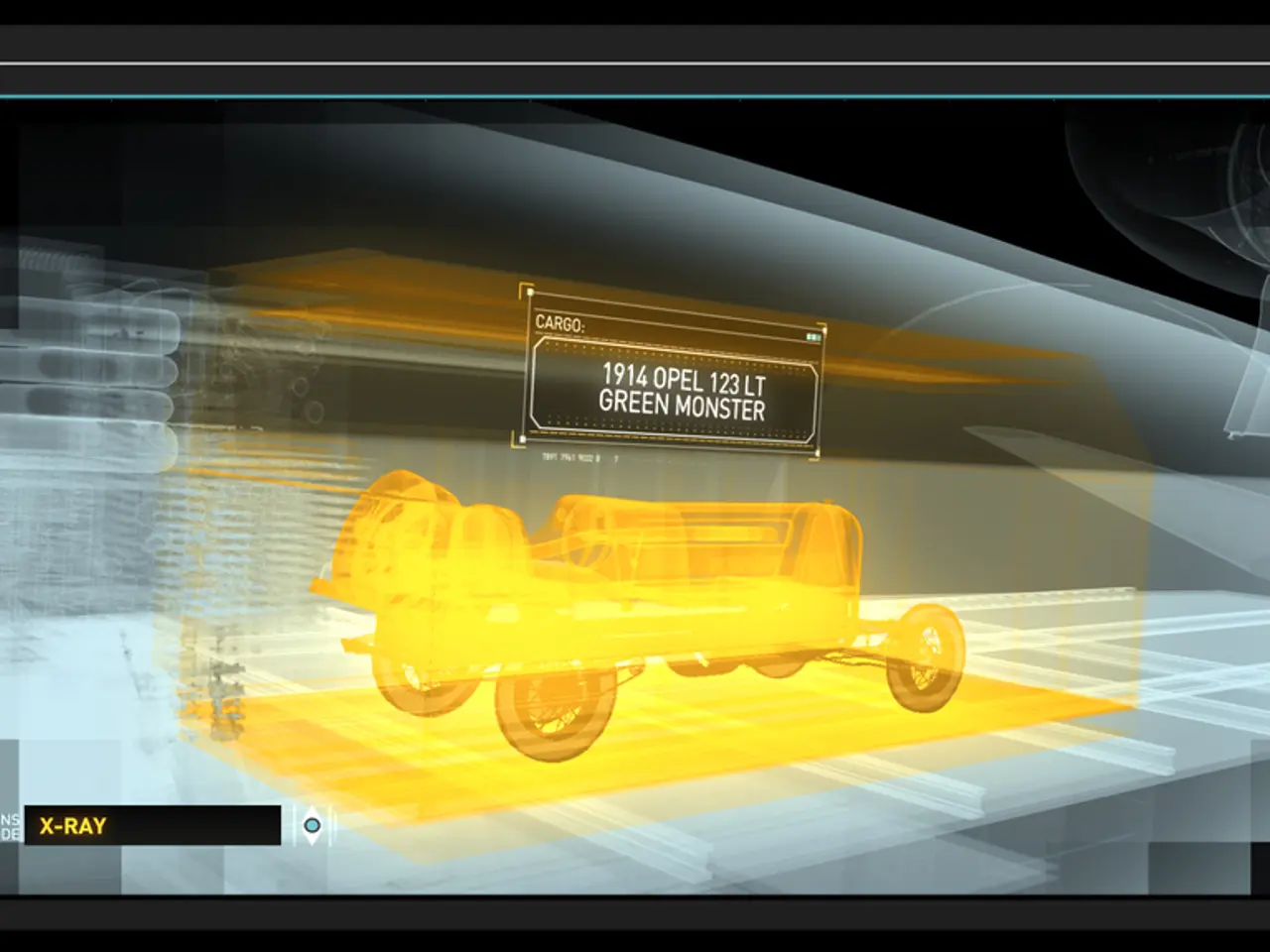

The researchers, led by Edwin Fohtung from Rensselaer Polytechnic Institute, used a process called solid state dewetting to prepare a sample for an extremely focused X-ray beam. This beam was used to mimic the environment inside a nuclear reactor, where materials are subjected to intense radiation.

For their experiments, the team studied nickel, a material commonly used in advanced nuclear reactor alloys. They discovered that by adding a buffer layer of silicon dioxide between the material and its substrate, and keeping the material under the X-ray beam for a longer period of time, they could improve the stability of the sample for real-time monitoring.

The interaction between nickel and the silicon substrate formed a new chemical compound, but adding a thin layer of silicon dioxide between the nickel and substrate prevented this reaction. This allowed the researchers to observe the formation of highly strained crystals on top of the buffer layer.

To accurately recover the 3D shape and size of these crystals, the team utilized phase retrieval algorithms, which allowed them to do so after a few extra minutes of X-rays. Interestingly, the researchers found that they could use the X-ray beam to precisely control the amount of strain in the material, which could have implications for the development of microelectronics.

The researchers also want to see how changing the thickness of the silicon dioxide buffer layer impacts their ability to control the strain in a crystal sample. They aim to apply this technique to more complex materials like steel and other metal alloys used in nuclear reactors and aerospace applications.

This research, which was published in the journal Scripta Materialia, was financially supported by institutions including the Deutsche Forschungsgemeinschaft (DFG), the Hans and Ria Messer Foundation, university internal funding bodies such as the Central Committee for Research and Knowledge Transfer at the University of Flensburg, the MIT Faculty Startup Fund, and the U.S. Department of Energy. The sample preparation was carried out, in part, at the MIT.nano facilities.

This work provides fundamental insight into how nanoscale materials respond to radiation and highlights the critical role of the substrate in strain relaxation. By reconstructing 3D image data on the structure of a material as it fails, researchers can design more resilient materials that can better withstand the stress caused by irradiation inside a nuclear reactor.

Read also:

- Nightly sweat episodes linked to GERD: Crucial insights explained

- Antitussives: List of Examples, Functions, Adverse Reactions, and Additional Details

- Asthma Diagnosis: Exploring FeNO Tests and Related Treatments

- Unfortunate Financial Disarray for a Family from California After an Expensive Emergency Room Visit with Their Burned Infant